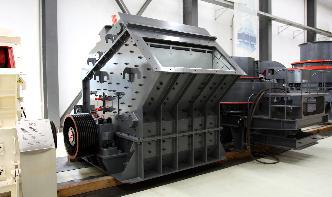

crushing process of ni ores

Processing Nickel Ores. One Mine's Nickel Processing of Pyrrhoite, Chalcopyrite and Pentalandite Ores. The ore is crushed to 5 inches in primary cone crushers, then reduced to 1/2"...